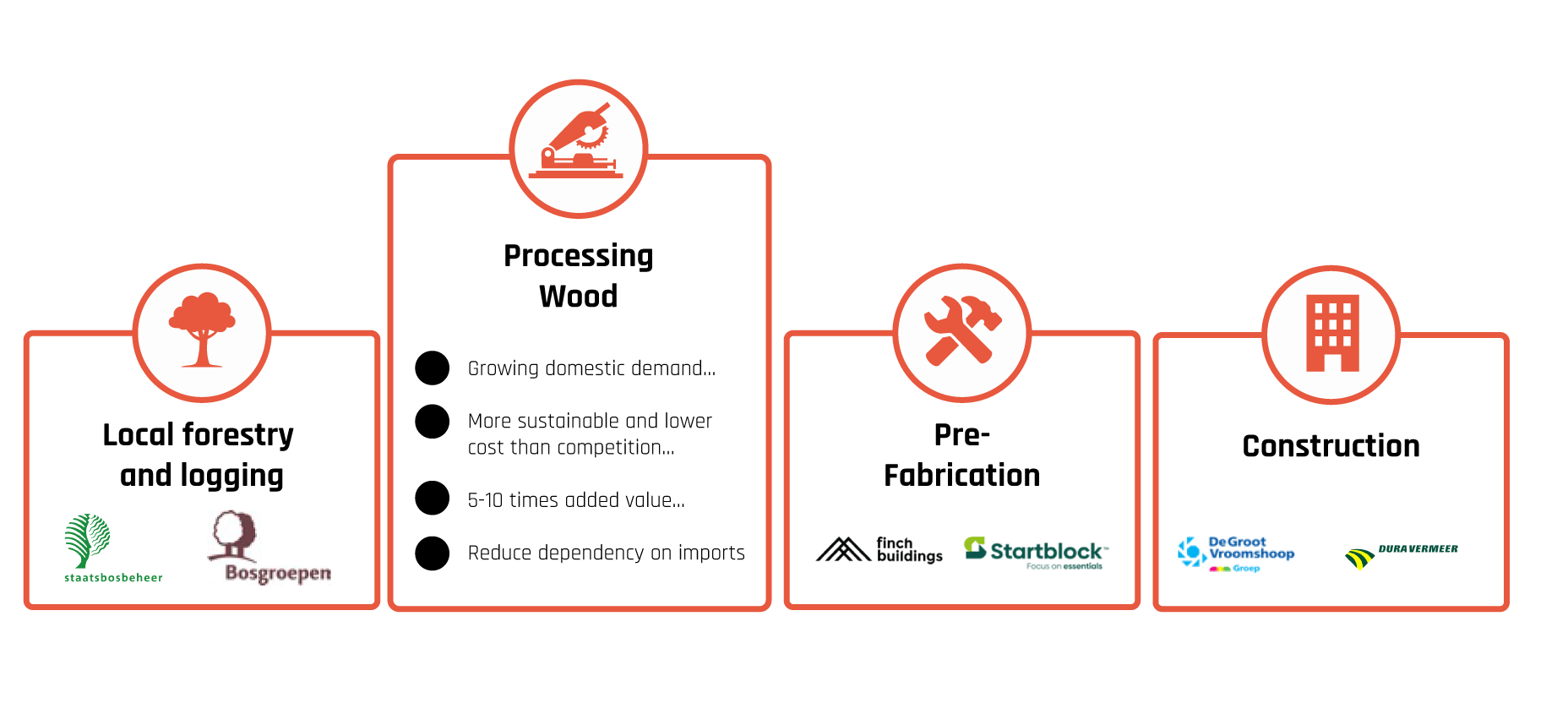

Domestic production of Engineered Wood is needed to truly make the transition from the“make-take-waste” economy to sustainable buildings

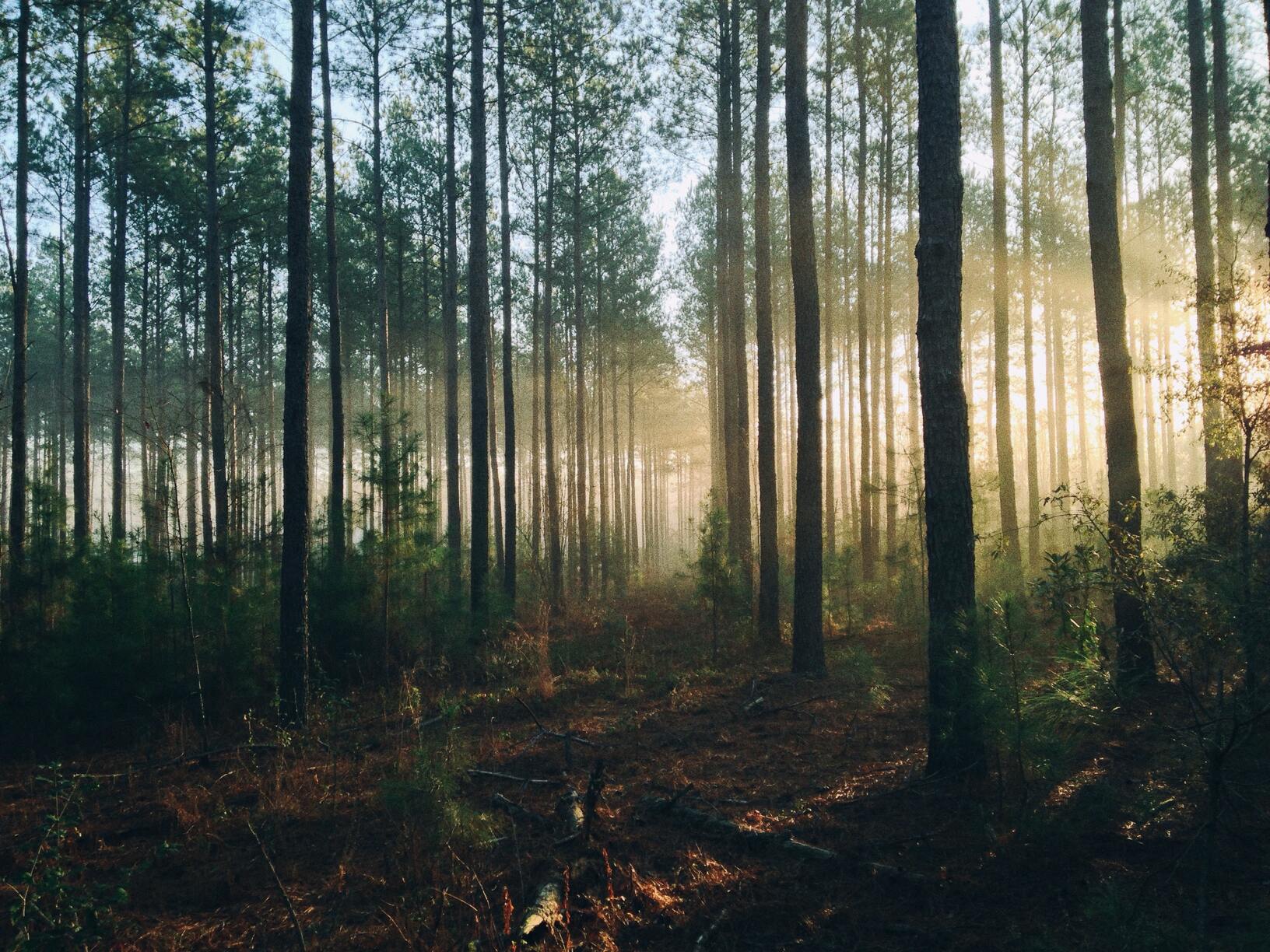

ARBORA aims to realize the first Dutch CLT production plant using domestic wood. We see an opportunity for local production of CLT, building the missing link in the Dutch bio-based materials value chain and contribute to the more than 1 million homes needed in the Netherlands between now and 2040. We will be using domestic timber, that is processed in a local plant, to make materials used in Dutch buildings

LEARN HOW